Mixed Mode Crack Analysis using XFEM

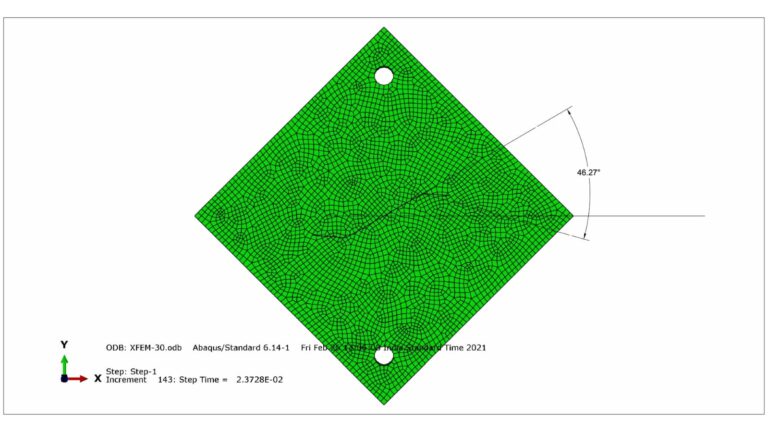

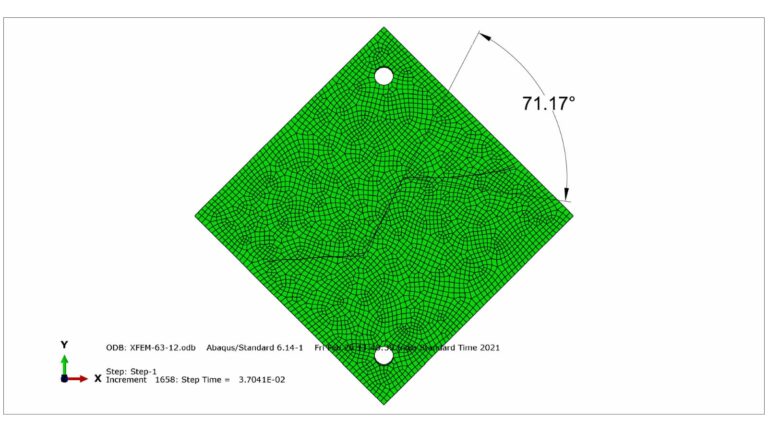

Project : Finite Element Analysis (FEA) is widely used in engineering to simulate stresses and deformations, but in this project we took it one step further by applying Extended Finite Element Method (XFEM) to simulate crack propagation in mechanical parts. Since no material in nature or manufacturing is perfect and flaws such as voids or micro-cracks are always present, our aim was to study how these imperfections behave under different loading conditions. To simulate this, we introduced micro-cracks at different angles in the model and analyzed them under varied loads. The work combined numerical simulation, theoretical validation, and experimental testing, providing a holistic study of fracture mechanics.

Role : As Team Lead, apart from leading the team, communicating with professors and lab managers, Documenting the reports; on the technical side, I was looking after theoretical approach, studying relevant fracture mechanics literature, and connecting theoretical concepts to simulation outputs. I also contributed to the experimental validation phase, working with acrylic specimens and UTM testing.

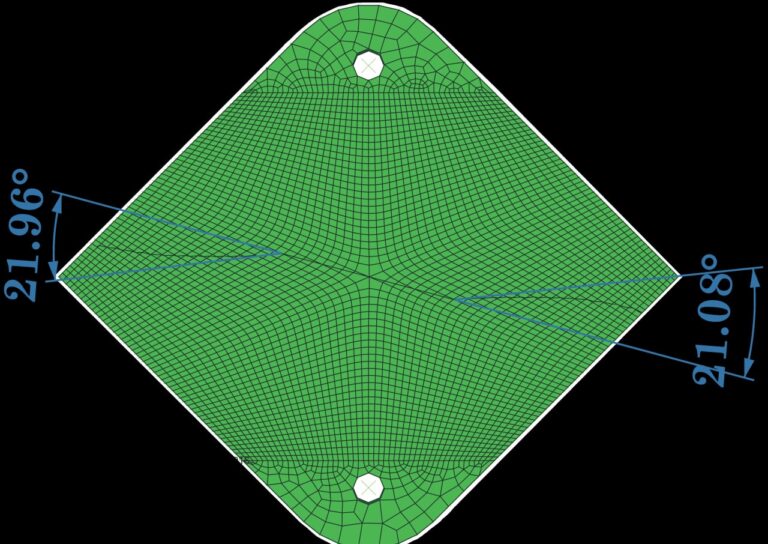

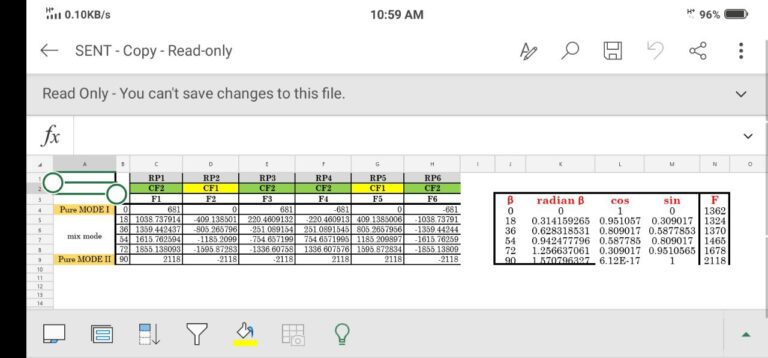

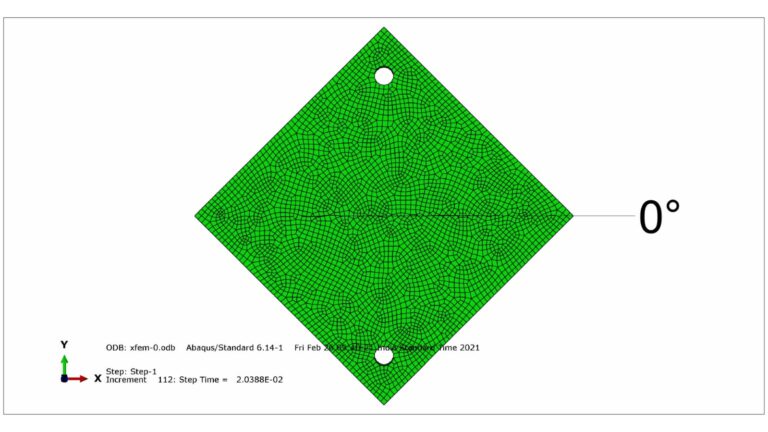

Action : I began by conducting a thorough literature review on fracture mechanics and XFEM. Using ABAQUS, I modeled parts with micro-cracks at different orientations and simulated them under multiple loading conditions. The simulation results were then compared with theoretical calculations to ensure accuracy. Taking it further, I collaborated in experimental validation, where we used a laser to create controlled micro-cracks in acrylic plates and tested them on a Universal Testing Machine (UTM). This step allowed us to compare simulation data with real-world experimental results.