Optimizing Assembly line – Cell Phones Manufacturing in Cyber Physical Lab

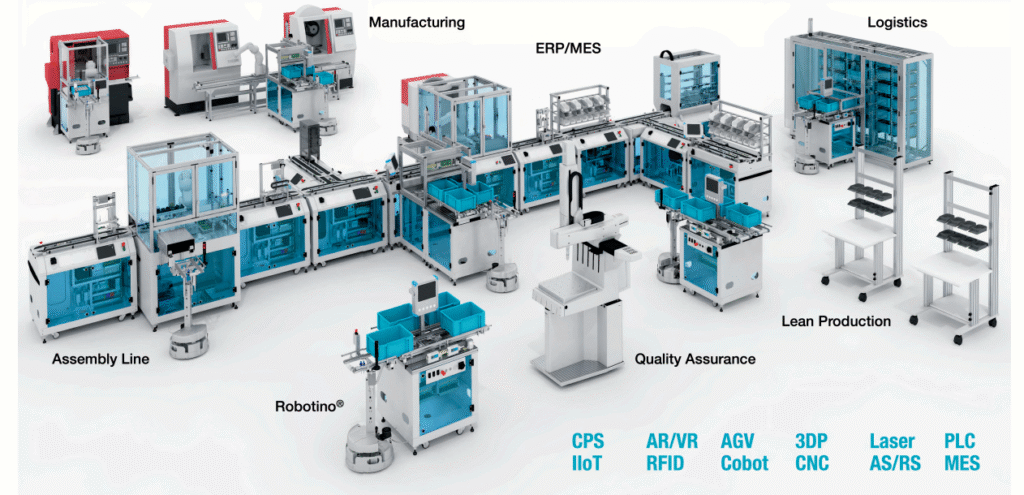

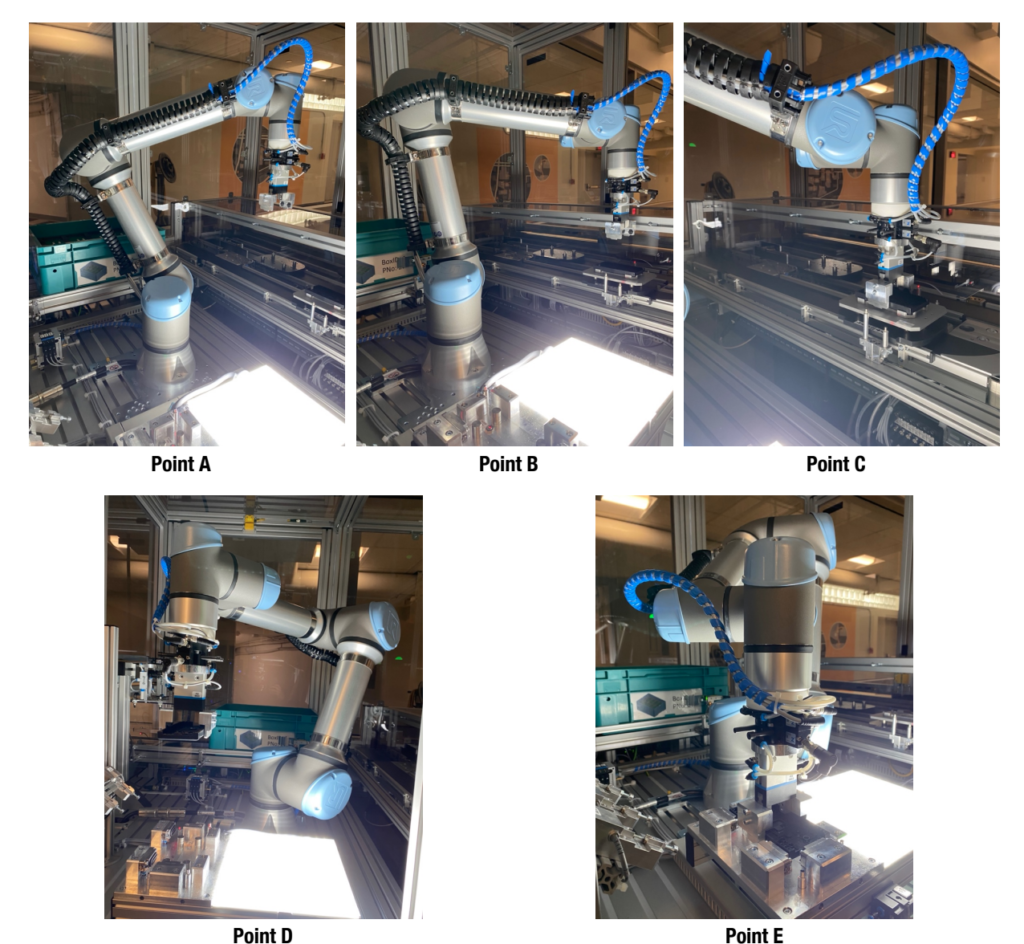

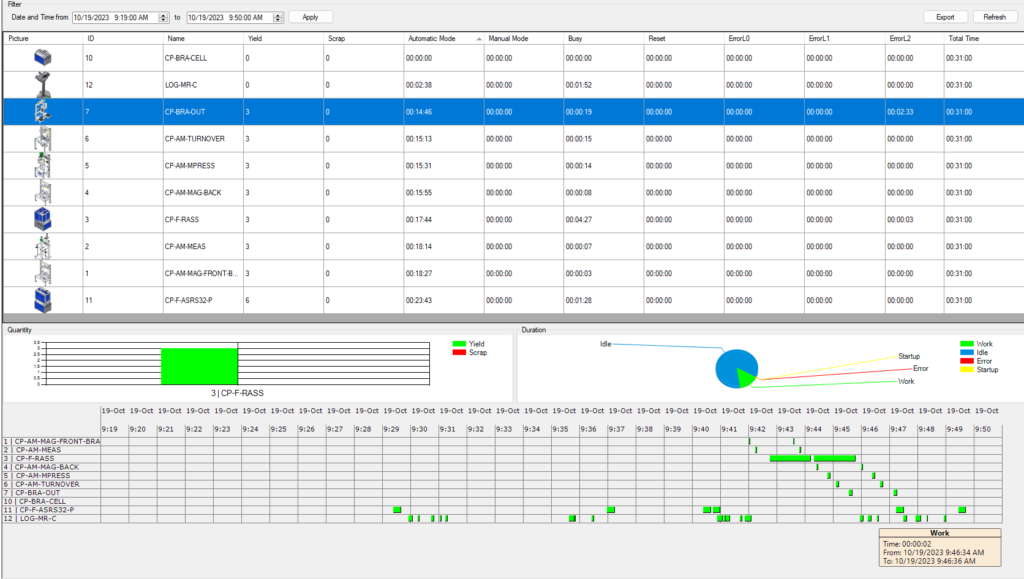

Project : At Northeastern University’s Boston campus, we explored a mini Cyber-Physical Factory that simulates a futuristic phone manufacturing line using FESTO machines, FANUC robots, and Robotino. Once the user specifies the required quantity, the system operates automatically: raw material is retrieved from the AS/RS system, carried by Robotino along the assembly line, inspected for defects, fitted with electrical components by a collaborative robotic arm, and finally completed by pressing the front cover. While the setup demonstrated the potential of Industry 4.0 automation, no structured study had been conducted on its workflow. We undertook this project independently to analyze the process, detect bottlenecks, and suggest improvements.

Role : I served as the team lead, taking responsibility for coordinating efforts, preparing technical documentation, and leading the bottleneck analysis. My role also extended to consolidating results into actionable solutions for system optimization.

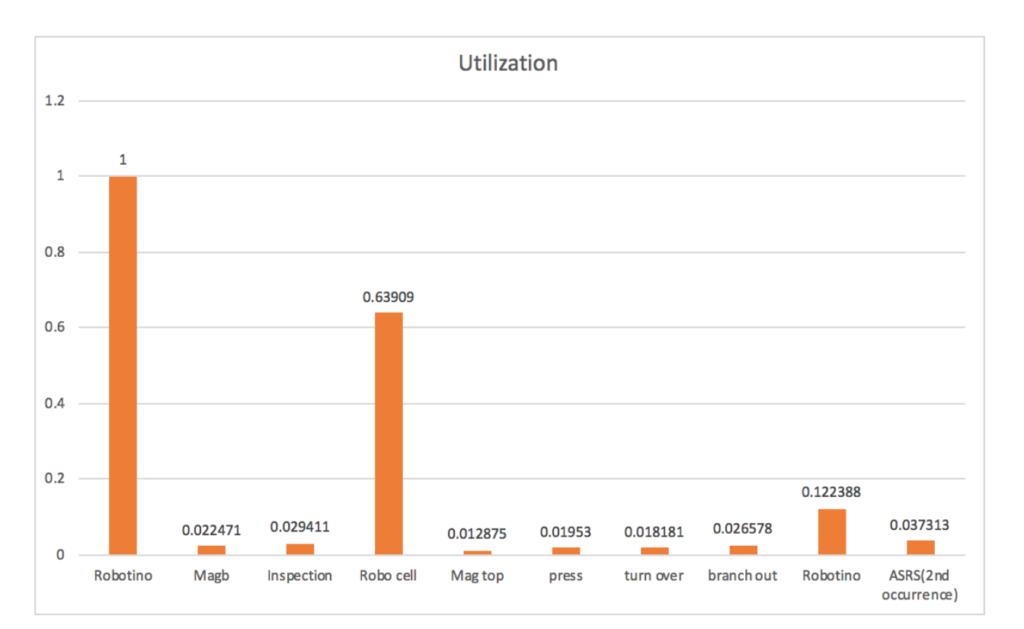

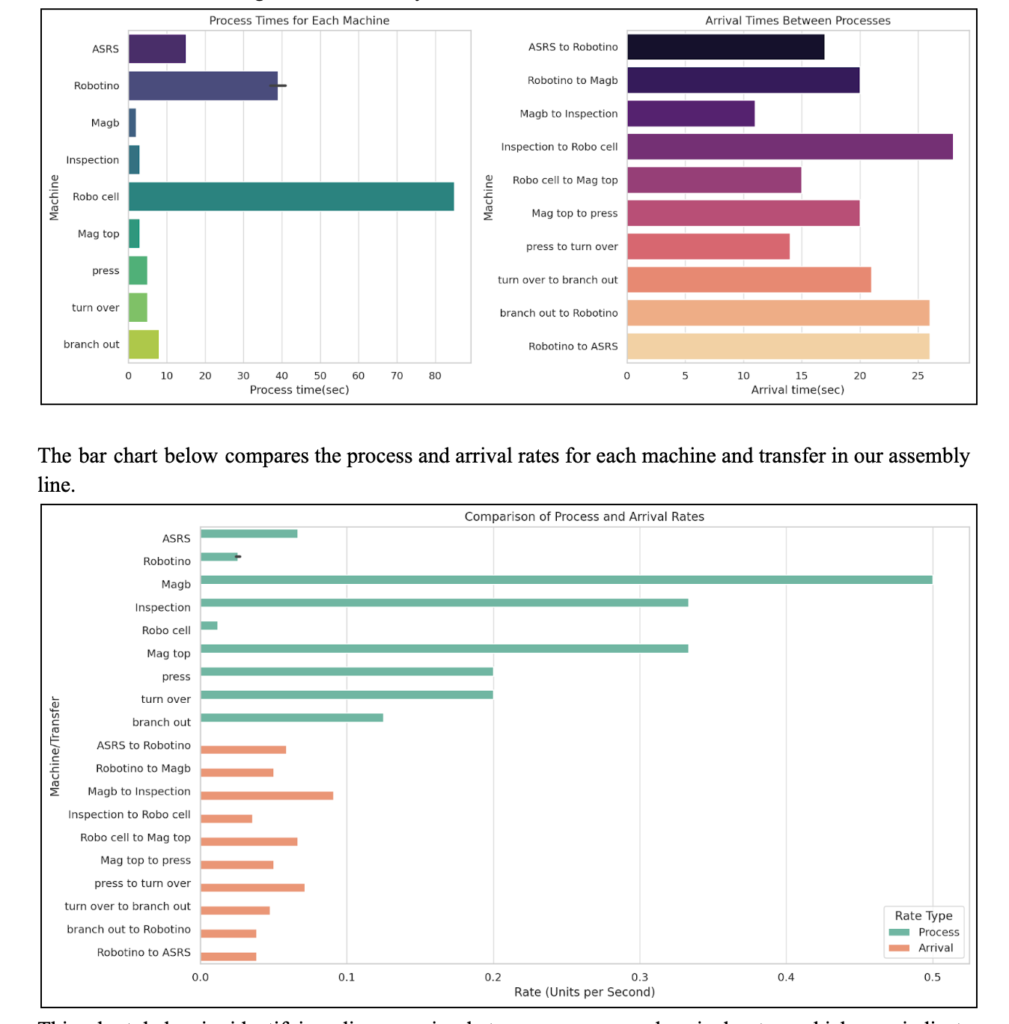

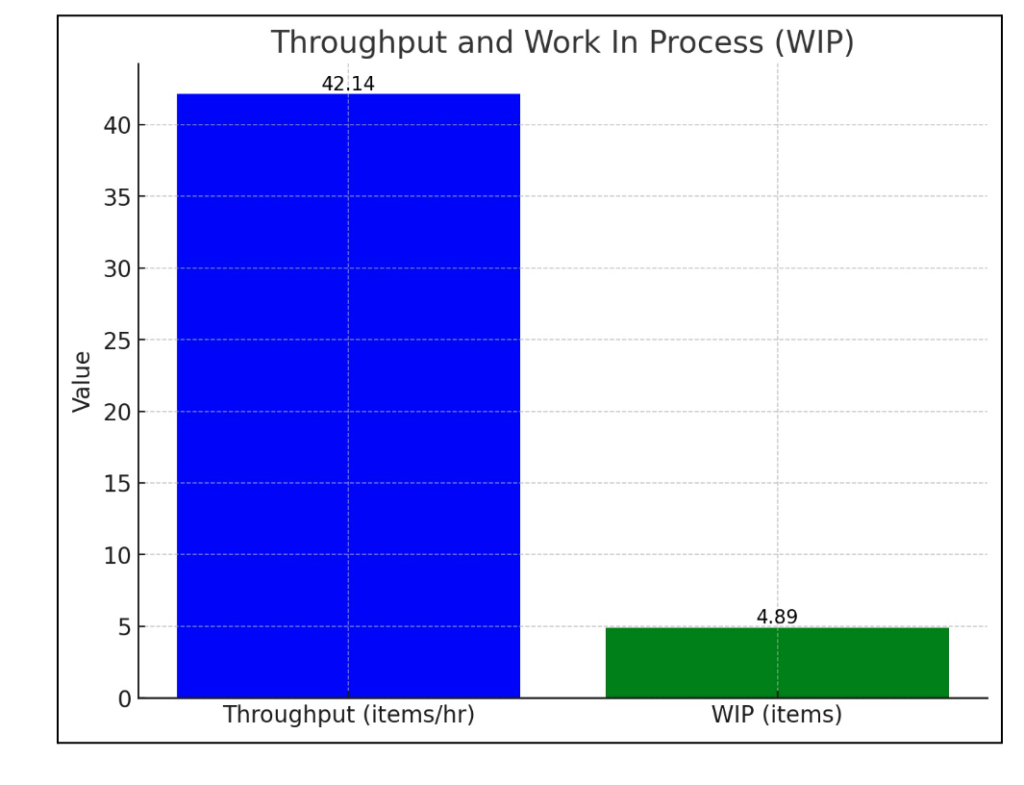

Action : I began by studying manufacturing concepts such as bottlenecks, WIP, and system throughput, and reviewed existing literature on cyber-physical factories. Using operational data from the lab, I documented the workflow step by step and analyzed each station’s performance. While at first the Robotino seemed to be the slowest element, detailed analysis revealed that the collaborative robotic arm was the actual bottleneck. Based on these findings, I contributed to developing solutions to re-balance the workflow, reduce production delays, and increase throughput.